Every structure we see — from skyscrapers to suburban homes — relies on the ground beneath it. Yet before walls rise and roofs take shape, the real work starts below the surface. The tools and techniques used to shape and prepare the earth are just as important as any blueprint. Whether it’s for stability, drainage, or precision placement of supports, the right groundwork determines the safety, longevity, and efficiency of the build. Among these methods, auger drilling has emerged as one of the most versatile ways to prepare the earth for everything from utility poles to building foundations. While other digging tools have their place, the auger offers a combination of speed, accuracy, and minimal disruption that makes it a go-to for both small-scale projects and large commercial developments. Understanding how and why it works can help you choose the right approach for your next project.

Why Ground Preparation Matters

Before a single brick is laid, the soil must be ready to bear the weight and function of the structure above it. Poor preparation can lead to uneven settling, drainage problems, and in extreme cases, structural failure. This is why builders and contractors invest time in assessing soil composition, moisture content, and load-bearing capacity before breaking ground. The right preparation also ensures that underground elements like pipes, conduits, or foundations are positioned precisely, preventing costly rework later.

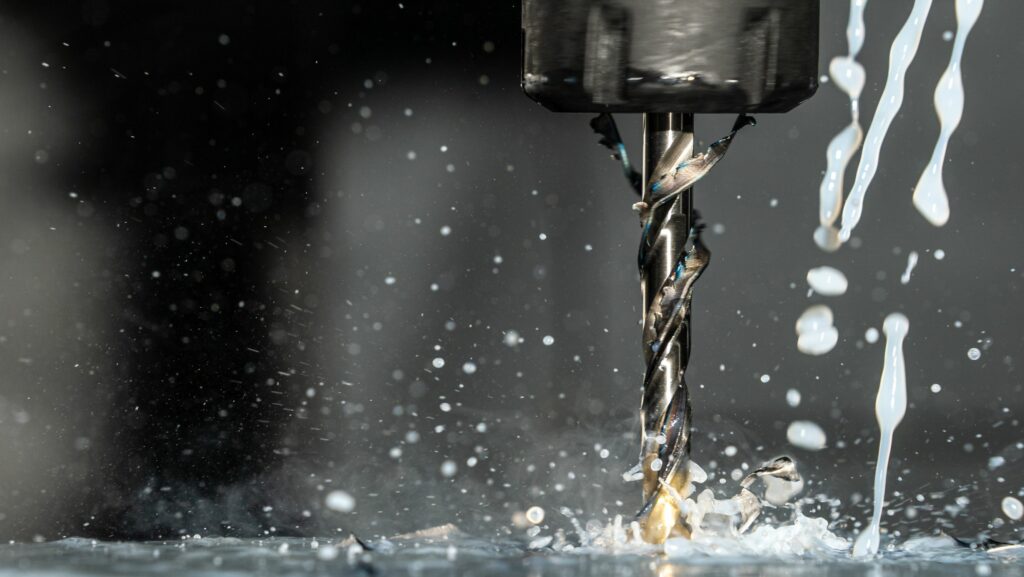

Different Tools for Different Jobs

Earthmoving equipment comes in many forms, each suited to specific conditions. Shovels and manual post-hole diggers are fine for small tasks in soft soil but are slow and labour-intensive. Excavators and backhoes move large volumes quickly but may be overkill for precision work. The auger sits between these extremes, offering enough power to handle tougher soils while producing clean, uniform holes ideal for structural supports. By reducing soil disturbance outside the drill path, it also helps maintain surrounding ground stability — important for projects near existing structures or landscaping.

Hand-Operated vs. Machine-Mounted

For smaller jobs, a hand-operated auger is light, portable, and affordable, making it popular for fence installations, signposts, or small tree planting. Powered augers, often gas- or electric-driven, increase efficiency for medium-sized projects. On the other end of the spectrum, machine-mounted augers attached to skid steers or excavators can drill through dense clay, gravel, or even frozen ground with relative ease. Choosing the right type depends on factors like soil condition, required depth, and the volume of holes needed.

Soil Assessment Before You Drill

Not all ground is equal, and a quick site inspection can save hours of frustration. Loose, sandy soils allow for fast drilling but may require reinforcement to prevent collapse. Clay offers strong support once compacted but can be difficult to cut through without the right equipment. Rocky ground poses the greatest challenge, as hitting large stones can stop drilling altogether or damage the auger blade. Identifying these conditions early means you can choose the correct drill bit, torque setting, and power source.

Applications Beyond Construction

While building projects are the most obvious use case, augers also play a role in agriculture, landscaping, and environmental work. Farmers use them to plant orchard trees or install irrigation systems. Landscapers rely on them for creating uniform planting holes or setting posts for decorative features. Environmental teams use augers to take soil samples for testing, helping assess contamination or suitability for planting. This versatility is one reason the tool has become a standard in so many industries.

Time, Labour, and Cost Benefits

Efficiency isn’t just about speed — it’s also about reducing labour strain and long-term expenses. Using an auger often means fewer workers are needed for the same amount of work, lowering payroll costs. Faster drilling speeds mean projects stay on schedule, and cleaner holes mean fewer mistakes to correct later. Over time, these savings can add up to a significant boost in profitability for contractors and construction firms.

Safety Considerations

While augers make drilling easier, they still require safe handling. Proper PPE — including gloves, boots, and eye protection — is essential. Workers should always be aware of underground utilities before starting, using maps or scanning tools to avoid dangerous strikes. Powered augers require stable footing and controlled operation, especially when working on slopes or in uneven terrain. Regular equipment maintenance also ensures safe and reliable performance.

Getting the Best Results

To maximise efficiency, start by clearly marking the drilling locations and checking alignment. Remove surface debris so the auger bit can engage with the soil cleanly. Let the auger do the work rather than forcing it — applying too much pressure can damage the bit or the machine. Periodically check depth and diameter to ensure each hole meets project specifications. And finally, plan ahead for where the excavated soil will go to avoid obstructing your work area.

Building from the Ground Up

Every successful project is built on a foundation of careful preparation and the right tools. From the smallest garden fence to the largest commercial structure, the principles are the same: know your soil, choose the right equipment, and work methodically. Tools like the auger bridge the gap between manual effort and heavy machinery, offering a balance of control, precision, and efficiency that keeps projects moving forward. When the ground is prepared with skill and the right technology, what’s built on top has a far better chance of standing strong for years to come.